First you need to saw through the lissome fiberglass using a. A wind turbines blades can be longer than a Boeing 747 wing so at the end of their lifespan they cant just be hauled away.

How To Service And Maintain A Wind Turbine Blade Windpower Monthly

What are the blades made of.

What are the blades on wind turbines made of. Iron or cast iron 5- 17. The technology used in manufacturing wind turbine blades has evolved over the past few decades. LM Wind Powers technology plays a central role in the creation of each wind turbine blade type.

Most of the body of the wind turbine is made of reinforced steel namely the tower. As a whole wind turbines are 85-90 recyclable. What are Wind Turbine Blades Made of.

New research is helping makers of. Design engineers aim for the smallest amount of drag. The smaller the drag the more efficient the turbine is in harvesting wind energy.

Blade making has evolved toward processes that make production cheaper and eliminate any manufacturing defects. For this reason the vast majority of wind turbines is the gondola blades towers or multipliers employees dedicated to wind production complexes. In a number of works the strength and damage mechanisms of hybrid composites were studied 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52.

Denmark is a strong proponent of wind power with wind turbines even appearing on the Faroe Islands. Fiberglass resin or plastic 11-16. A stereotypical wind turbine is designed to feature three rotor blades.

In contrast the blades are made of a composite material consisting of glass fabric and carbon fiber infused with liquid plastic. A wind turbine consists of three main components. Almost every single megawatt-sized turbine blade produced today has been made with a thermal set material such as epoxy vinyl ester or polyester said Berry.

Each wind turbine blade takes two days and 100 employees to manufacture. Typically the only area of a wind turbine blade used in the calculation of drag is the front area leading edge of the blade. This design consideration has to do with aerodynamics drag stability of the turbine and cost efficiency.

In fact the very earliest prototype wind turbine blades were made from a variety of materials including balsa wood Bakelite an early version of plastic and rubber. The world currently longest wind turbine rotor blade the 884 m long blade from LM Wind Power is made of carbonglass hybrid composites. Siemens Gamesa started producing turbine blades in Hull in 2016 and winning the Hornsea Two project is a boost for the factory.

Factors such as wind turbine blade materials aerodynamics blade profile and structure define the performance and reliability of the LM Wind Power blade and these turbine blade design factors all require an extremely high degree of precision. Although thermoplastic resin systems are new to wind they have been around a long time in other industries. There have been a number of design considerations put into wind turbines both on-shore and off-shore one of which is the number of rotor blades.

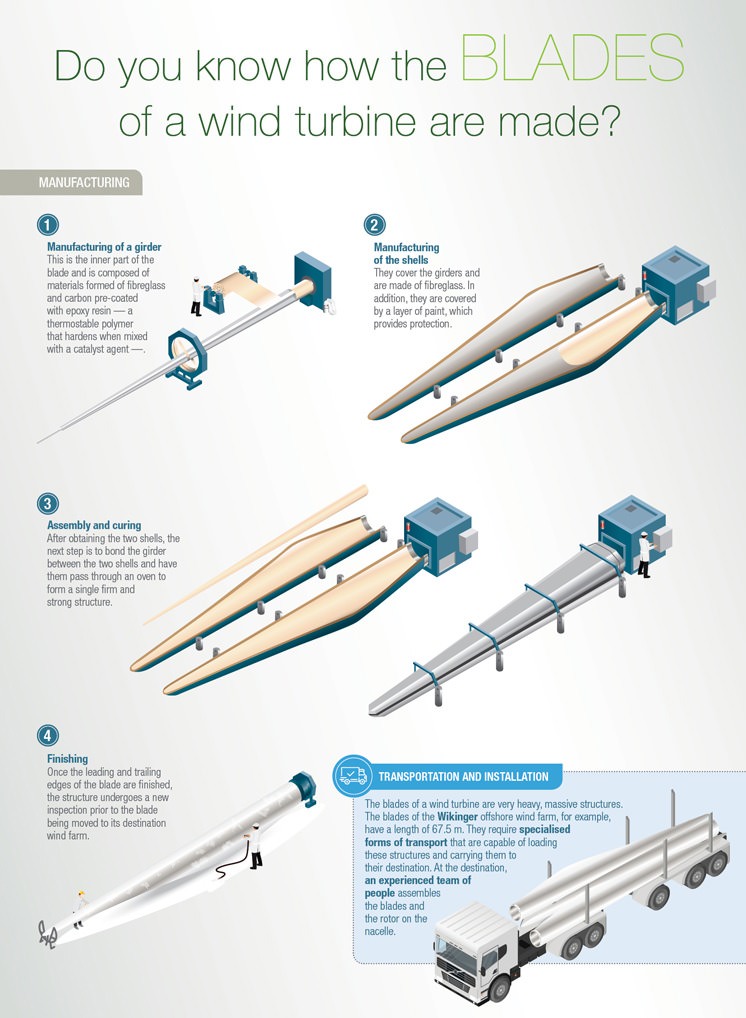

They cover the girders and are made of fibreglass. The blades of a wind turbine are made of several layers of glass or carbon fiber infused with a liquid plastic resin. Unlike the rest of the wind turbines components wind turbine blades are made of resin and fiberglass which are difficult materials to reuse or recycle.

This is the inner part of the blade and is composed of materials formed of fibreglass and carbon pre-coated with epoxy resin - a thermostable polymer that hardens when mixed with a catalyst agent. The wind farm should. American-made wind turbine blades.

This creates a composite material that is strong durable and lightweight giving the wind turbine a long lifespan. The tower nacelle and rotor blades. Manufacturing of the beam.

The Dutch city boasts a 1200sq m childrens playground called Wikado with a slide tower tunnels ramps and slides all made from five discarded wind turbine blades. The generator and gearbox are also composed of several metal alloys. Manufacturing of the shells.

This is according to a report from the National Renewable Energy Laboratory. Iron or cast iron 5- 17. The process to assemble a wind turbine is carefully orchestratedtheres a lot to manage including the wind turbine materials.

Traditionally wind turbines are a combination of steel 71-79 of total turbine mass fiberglass resin or plastic 11-16. What is the Best Composition of the Wind Turbine Blades. To reduce drag blades are made relatively narrow.

The principle design of commercial turbines today are horizontal axis wind turbines consisting of a rotor with three fiberglass blades attached to a hub which is itself attached to a central piece the nacelle that is mounted on a steel tower. The tower provides structural support upon which the nacelle and rotor blades stand and is made of tubular steel concrete or steel lattice. First workers make the blades from fiberglass fabric and balsa wood.

According to a report from the National Renewable Energy Laboratory wind turbines are predominantly made of steel 71-79 of total turbine mass. Its the wind turbine blades that are the problem.

Innovative Wind Turbine Blade Manufacturing Ge Renewable Energy

Balsa Wood Structure In Wind Turbine Blades 18 Download Scientific Diagram

Wind Turbines Blades Iberdrola